Projects

Fixtures

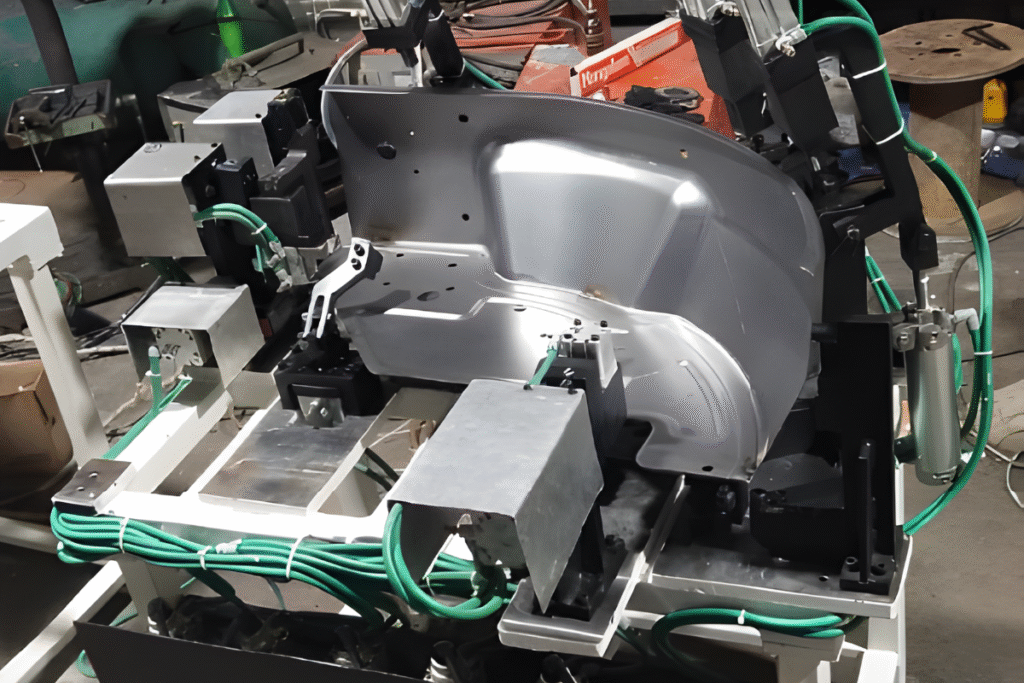

The Fender Project by Mechalogic Automation demonstrates our expertise in delivering custom-designed spot and MIG welding fixtures for complex automotive body components. Developed with precision engineering and advanced clamping systems, these fixtures ensure accurate alignment, superior weld quality, and production efficiency during fender assembly.

Each fixture is designed to handle high-speed robotic and manual welding operations, ensuring consistent results and reduced downtime. With a focus on durability, precision, and operator convenience, our fender welding setups are trusted by leading automotive manufacturers for their reliability and performance.

Highlights

-

Precision-engineered for accurate and stable cutting operations

-

Designed to withstand heat and mechanical stress

-

Fast setup with ergonomic and user-friendly design

-

Compatible with both CO₂ and fiber laser machines

-

Long-lasting and maintenance-friendly construction

-

Fully customizable to suit your production needs

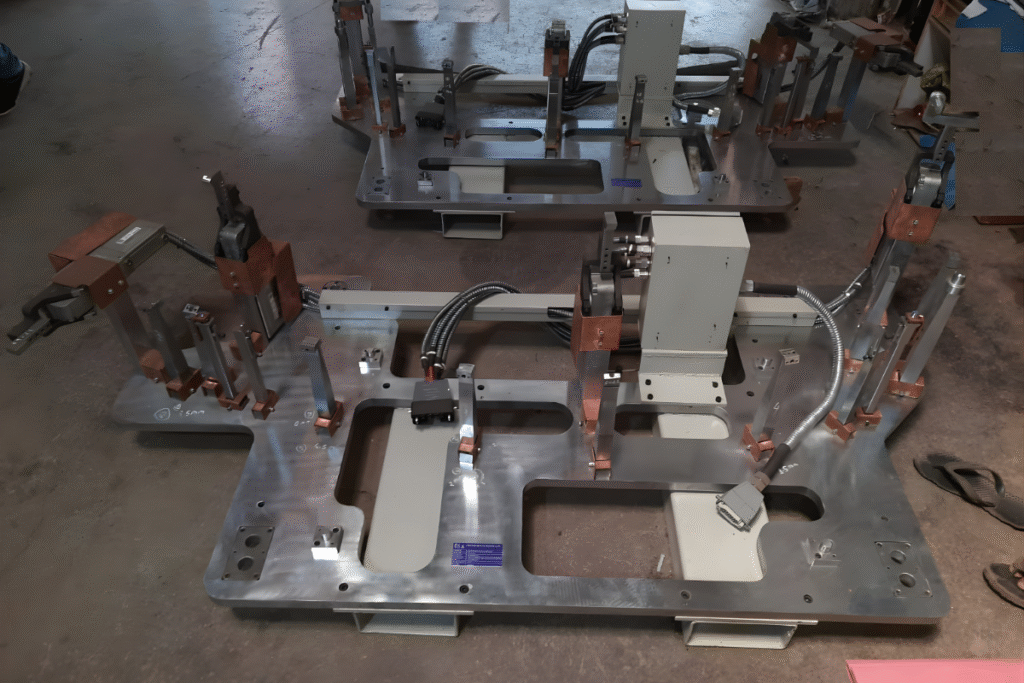

Spot Welding Fixtures

Mechalogic Automation specializes in designing and manufacturing spot welding fixtures that ensure perfect alignment, repeatability, and strength during welding operations. Each fixture is engineered for high precision and durability, helping manufacturers maintain consistent weld quality in high-volume production environments.

Our spot welding fixtures are widely used in automotive, fabrication, and industrial assembly lines, supporting both manual and robotic welding applications. Built with robust materials and advanced clamping systems, these fixtures deliver stable positioning, minimal distortion, and long-term performance.

Highlights

Accurate and repeatable weld positioning

Heavy-duty structure to resist vibration and heat

Compatible with robotic and manual spot welding setups

Motorized or hydraulic clamping for faster cycle times

Low maintenance and long service life

Fully customizable to match component geometry and production needs

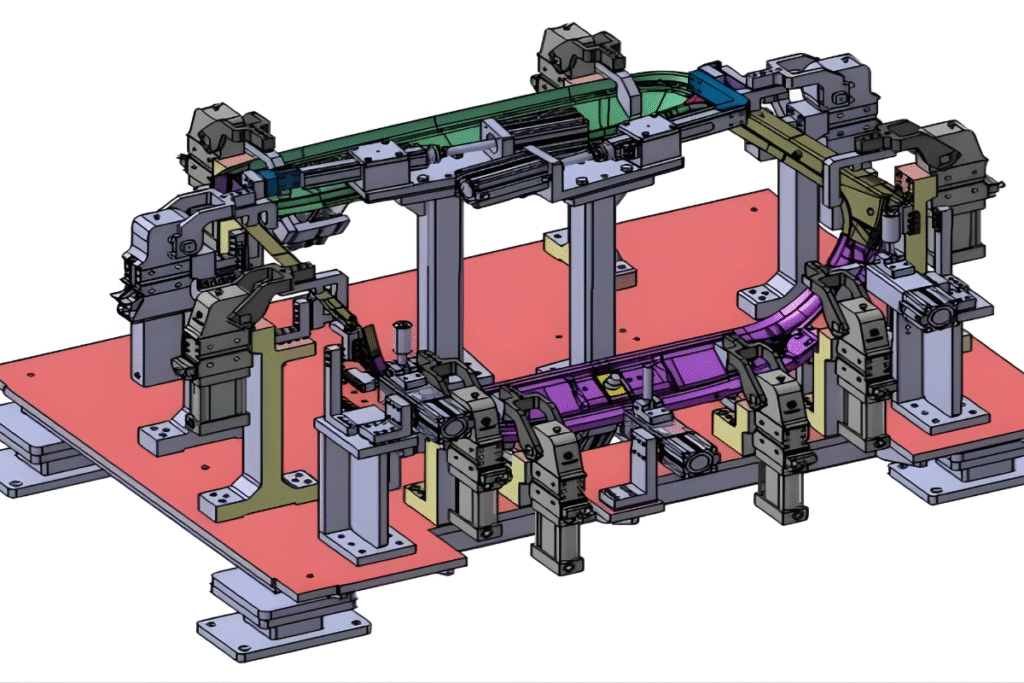

Fender Project

At Mechalogic Automation, we design and manufacture high-performance fixtures that guarantee accuracy, efficiency, and long-term reliability. Each fixture is developed using advanced CAD/CAM technology to ensure precise part positioning, strong clamping, and minimal vibration during the process. Our fixtures are widely used in automotive, fabrication, and heavy engineering industries, where precision and repeatability are critical. With a focus on quality and performance, every fixture is built to deliver stable support, faster cycle times, and consistent results even under continuous production conditions.

Highlights

Precision fixture design for accurate fender positioning

Compatible with both MIG and spot welding applications

Strong and stable structure for vibration-free operation

Motorized or hydraulic clamping for fast, secure setup

Easy maintenance and ergonomic layout

Built for consistent weld quality in mass production

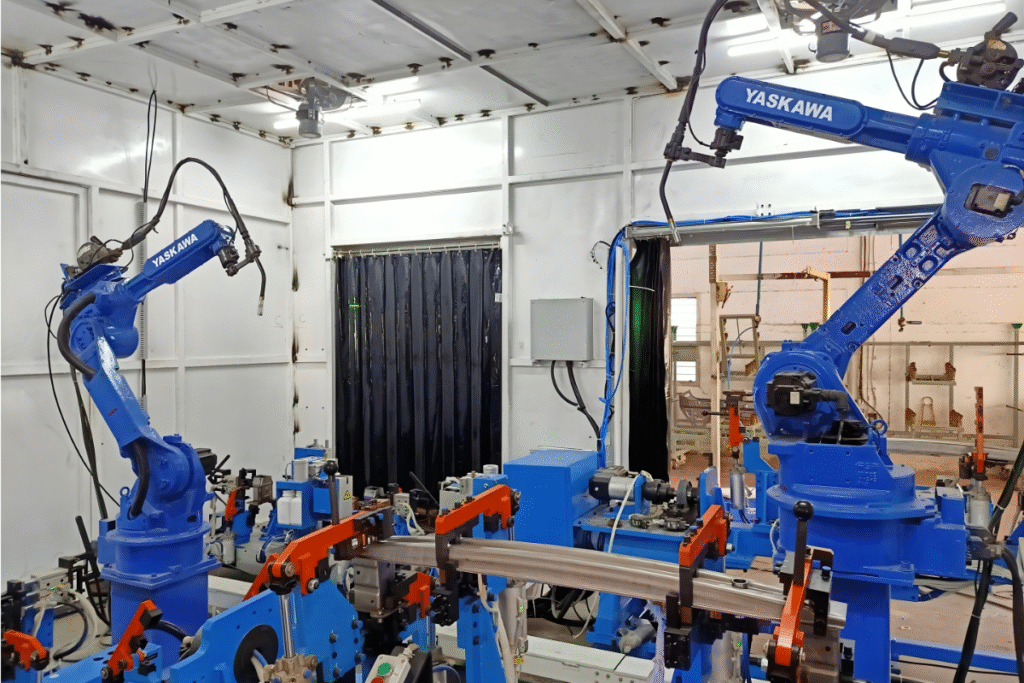

Welding Robot Cell Motorized Door

Mechalogic Automation designs and builds advanced welding robot cells integrated with motorized door systems for safe, efficient, and automated welding operations. These cells are engineered for MIG, CO₂, and spot welding applications, offering seamless automation and enhanced operator safety.

The motorized door mechanism enables smooth, automatic opening and closing synchronized with the robot’s operation — reducing manual handling and increasing production speed. Built with high-quality materials and precision design, our robotic cells ensure vibration-free performance, easy maintenance, and long-term reliability.

Highlights

Fully automated motorized door system for faster cycle times

Compatible with robotic MIG, CO₂, and spot welding processes

Strong, vibration-free structure ensuring stable weld quality

Safety interlocks and light curtain systems for operator protection

Compact design with easy access for maintenance and operation

Compatible with Fanuc, ABB, KUKA, Yaskawa, and other leading robot brands

Built for high-volume, precision-oriented manufacturing environments

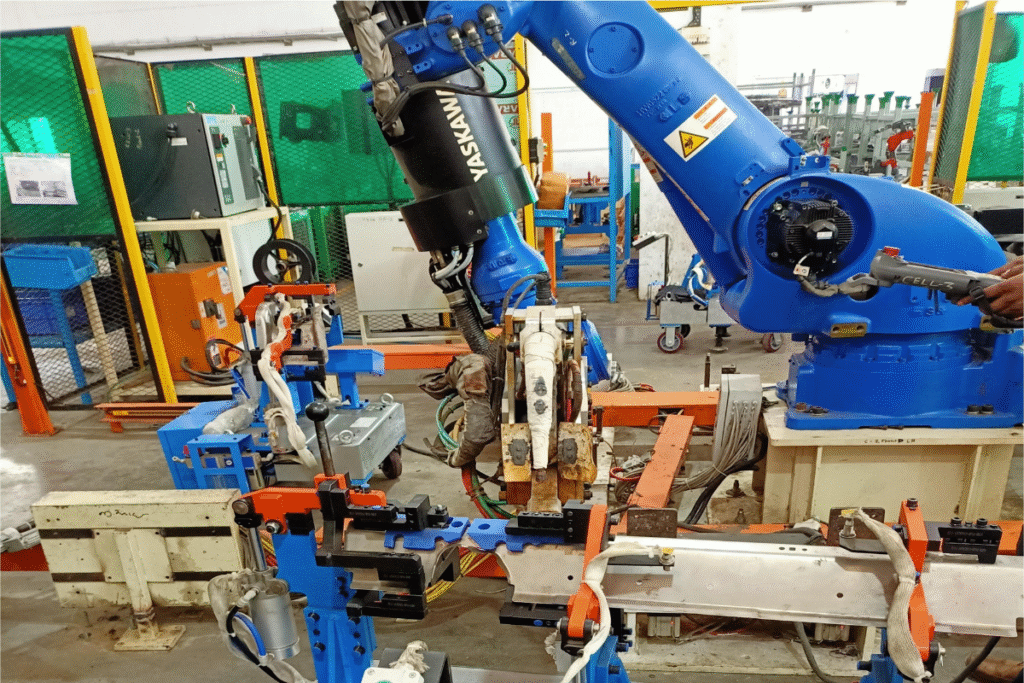

Mig Welding Robot Cell and PLC Panel Gujarat Caparo

Mechalogic Automation successfully executed the MIG Welding Robot Cell and PLC Panel Project for Gujarat Caparo, delivering a fully automated and precision-controlled welding system. This project showcases our expertise in robotic integration, control automation, and system optimization for high-performance manufacturing environments.

The MIG Welding Robot Cell is designed for consistent weld quality, high productivity, and operational safety. It integrates a custom-built PLC control panel that synchronizes the robot, safety systems, and peripheral devices for smooth, coordinated operation. With advanced programming and real-time monitoring, the system ensures seamless automation from start to finish.

Highlights

High-precision MIG robotic welding cell for automotive components

Integrated PLC control panel for automation and process synchronization

Multi-axis robotic control for complex welding operations

Optimized layout ensuring space efficiency and easy maintenance

Real-time process monitoring and parameter control via HMI interface

Safe and reliable operation with interlocks and system diagnostics

Designed for continuous, high-volume production at Gujarat Caparo

Spot Welding Robot Cell Gujarat Caparo

At Mechalogic Automation, we design and manufacture high-performance fixtures that guarantee accuracy, efficiency, and long-term reliability. Each fixture is developed using advanced CAD/CAM technology to ensure precise part positioning, strong clamping, and minimal vibration during the process.

Our fixtures are widely used in automotive, fabrication, and heavy engineering industries, where precision and repeatability are critical. With a focus on quality and performance, every fixture is built to deliver stable support, faster cycle times, and consistent results even under continuous production conditions.

Highlights

Fully automated spot welding robotic cell for precision manufacturing

Designed and executed for Gujarat Caparo automotive plant

High repeatability and accuracy in weld positioning

Integration with PLC control and safety interlocks

Compact, robust structure for stable, vibration-free operation

Compatible with leading robot brands like Fanuc, ABB, KUKA, and Yaskawa

Enhanced operator safety with sensors, guards, and motorized doors

Built for continuous production with minimal maintenance

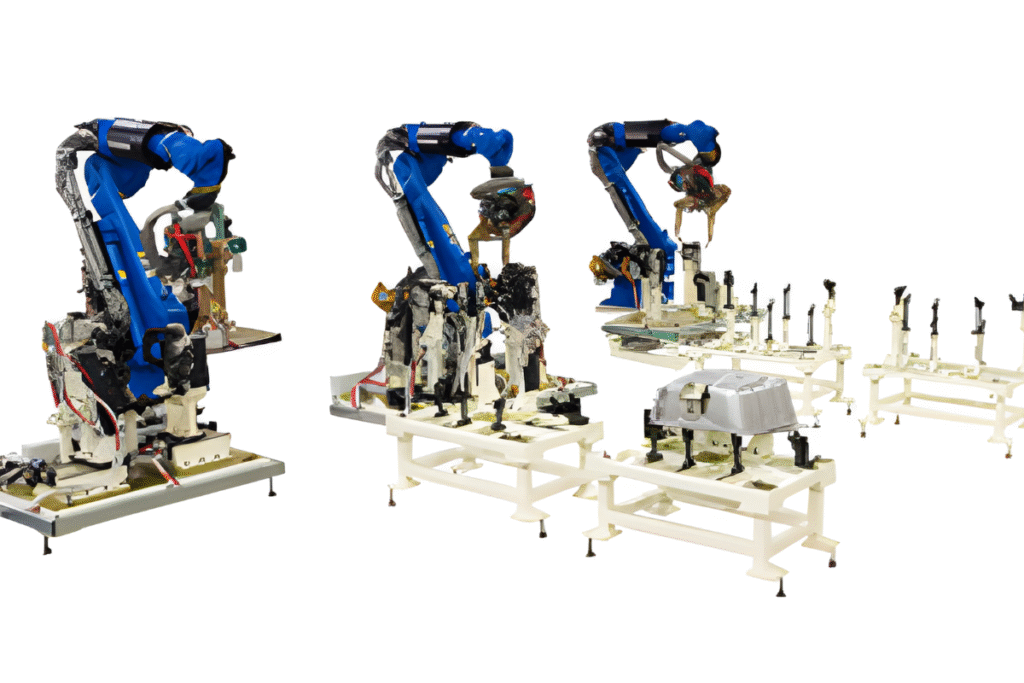

Robot Simulation Projects

At Mechalogic Automation, we operate among the leading fixture manufacturing companies in Pune; we provide advanced robot simulation and optimization services to help industries plan, validate, and enhance their automation systems before actual implementation. Our simulation projects focus on achieving the perfect balance between productivity, accuracy, and cost efficiency, ensuring smooth robot integration and optimal cell performance.

Using industry-standard simulation software, our team designs complete robotic cells virtually — including cell layout, robot path planning, gun reach studies, and cycle time optimization. This process allows us to identify potential issues early, optimize the layout, and reduce commissioning time on the shop floor. Whether it’s spot welding, MIG welding, arc welding, or material handling, our simulations guarantee maximum robot efficiency and zero collisions.

Highlights

Complete robot cell simulation and validation before installation

Reach and accessibility studies for robotic arms and end tools

Cycle time optimization for higher production output

Simulation for spot, MIG, and arc welding, and material handling applications

Accurate gun and torch path planning for collision-free operation

Integration with real-world PLC and robot control logic

Reduced commissioning time and on-site debugging

Customized simulation reports with visuals and process documentation

Spot Welding Fixtures

Highlights

-

Accurate and repeatable weld positioning

-

Heavy-duty structure to resist vibration and heat

-

Compatible with robotic and manual spot welding setups

-

Motorized or hydraulic clamping for faster cycle times

-

Low maintenance and long service life

-

Fully customizable to match component geometry and production needs