Industrial Automation Project

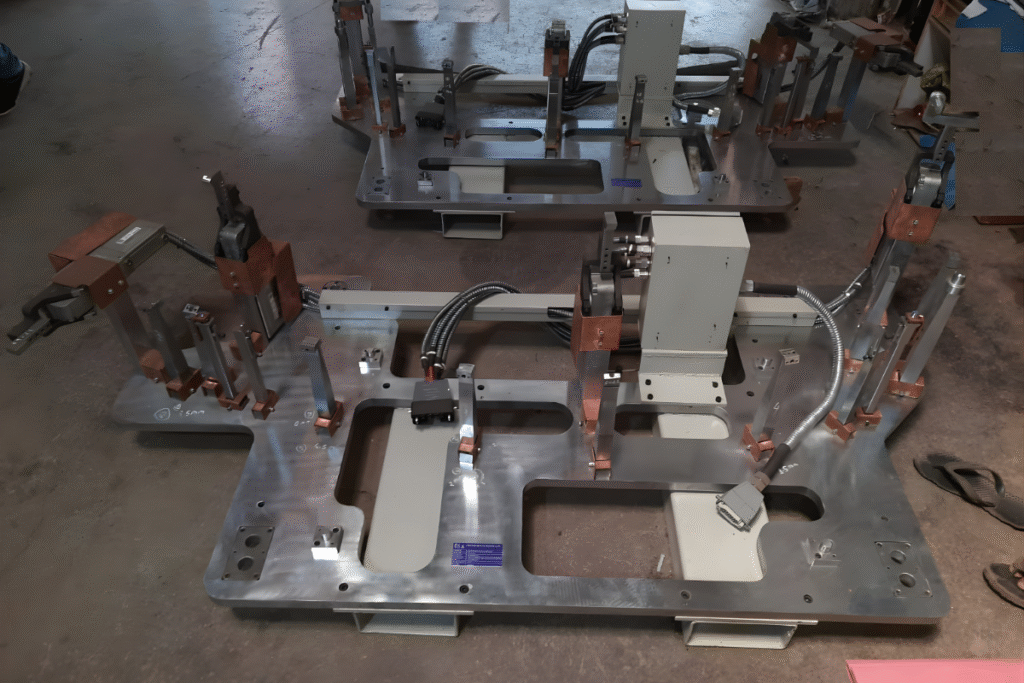

Fixtures

Mechalogic Automation is among the trusted fixture manufacturers in Pune, specializing in the design and manufacturing of high-precision fixtures that ensure accurate positioning, rigid clamping, and stable support of components during the manufacturing process. As experienced welding fixture manufacturers in Pune, our solutions are engineered to withstand high thermal and mechanical stresses while maintaining tight tolerances for consistent, high-quality output.

Designed using advanced CAD/CAM tools, our fixtures enhance cutting and welding accuracy, reduce setup time, and improve overall production efficiency. Each fixture is custom-built to match specific part geometries, material requirements, and production needs, ensuring seamless integration with existing manufacturing and automation systems.

Key Features

- High-precision design for accurate component positioning.

- Rigid and durable structure to minimize vibration and thermal distortion.

- Quick clamping and unclamping system for faster cycle times.

- Compatibility with CO₂ and fiber laser cutting machines.

- Corrosion-resistant surface finish for long operational life.

- Easy maintenance and ergonomic operation.

- Customizable design to suit part size and laser application.

- Enhanced productivity and reduced setup errors.

Spot Welding Fixtures

Mechalogic Automation is among the trusted fixture manufacturers in Pune, specializing in the design and manufacture of high-performance spot welding fixtures for automotive, industrial, and fabrication applications. As experienced welding fixture manufacturers in Pune, we engineer fixtures that ensure precise part location, strong clamping, and repeatable weld quality for consistent and reliable production output.

Our spot welding fixtures are built using durable materials and precision components, making them suitable for both manual and robotic welding operations. Each fixture is custom-designed to match specific part geometry, welding sequences, and electrode accessibility, ensuring stable performance even in high-speed manufacturing environments. With a strong focus on ergonomics, productivity, and quality, Mechalogic Automation helps manufacturers reduce downtime and achieve superior welding accuracy across every production cycle.

Key Features

- Precision alignment for accurate and repeatable weld positions

- Heavy-duty and rigid structure to ensure stability during welding

- Suitable for both robotic and manual spot welding applications

- Quick-change clamping systems for faster setup and part replacement

- Integration with pneumatic or hydraulic clamping mechanisms

- Optimized design for heat dissipation and reduced distortion

- Low maintenance with long operational life

- Custom-built to match specific product and production line requirements

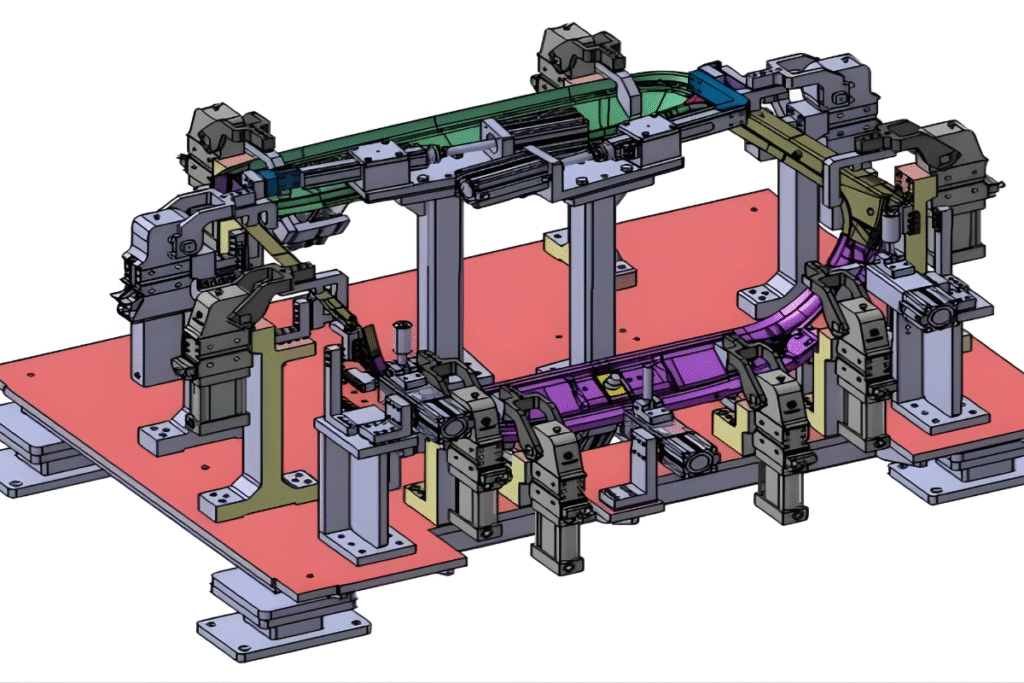

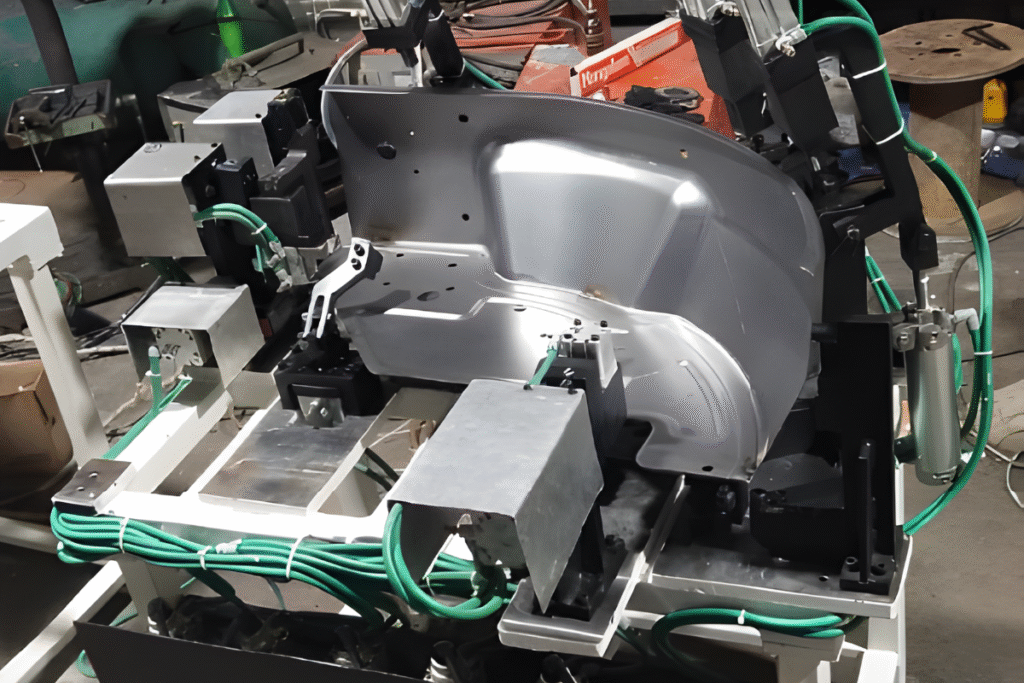

Fender Project

The Fender Project by Mechalogic Automation showcases our expertise in designing and fabricating spot welding and MIG welding fixtures specifically developed for fender assembly applications in the automotive sector. These fixtures are built to ensure perfect alignment, accuracy, and stability of complex sheet metal components during welding operations. Designed with robust construction and advanced clamping mechanisms, the fixtures help achieve uniform weld penetration and high repeatability across multiple production cycles. Our fender welding setups are compatible with both robotic and manual welding stations, enabling flexibility and reliability in high-volume manufacturing lines.

Key Features

- Precision-engineered for accurate fender part positioning and alignment.

- Supports both MIG and Spot Welding operations

- Rigid structure with anti-vibration design for consistent weld quality.

- Pneumatic or hydraulic clamping for quick and secure workholding

- Compatible with robotic arms and automated welding cells.

- Ergonomic fixture layout for easy operator access and maintenance.

- Durable construction ensuring long service life and reduced downtime.

- Tailored design as per customer-specific fender geometry and production requirements.

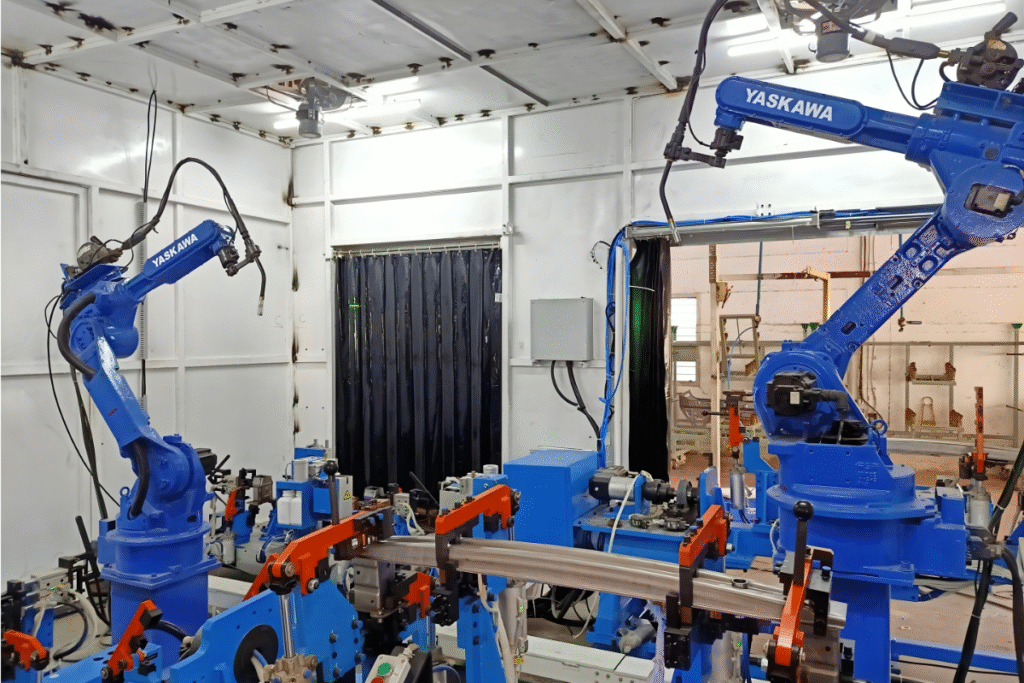

Welding Robot Cell – Motorized Door

Mechalogic Automation specializes in designing and building advanced welding robot cells integrated with motorized door systems to enhance safety, efficiency, and productivity in automated welding operations. These cells are developed for both MIG and spot welding applications, ensuring precision, consistency, and reliability in every weld. The motorized door mechanism allows smooth, automatic opening and closing during the welding cycle, minimizing manual intervention and ensuring operator safety. Each robot cell is designed with optimal accessibility for maintenance, compact layout for space efficiency, and compatibility with leading robot brands such as Fanuc, ABB, KUKA, and Yaskawa.

Key Features

- Fully automated motorized door system for enhanced safety and faster cycle times.

- Integrated robotic welding setup for CO₂, MIG, or spot welding processes

- Strong and rigid base frame ensuring vibration-free operation.

- Optimized design for heat dissipation and reduced distortion

- Low maintenance with long operational life

- Custom-built to match specific product and production line requirements

MIG Welding Robot Cell and PLC Panel – Gujarat Caparo

Mechalogic Automation successfully executed the MIG Welding Robot Cell and PLC Panel project for Gujarat Caparo, showcasing our expertise in robotic welding automation and industrial control integration. The project involved the design, fabrication, and commissioning of a fully automated MIG welding cell equipped with a custom-built PLC control panel to manage and monitor the entire process with precision. This robotic system ensures high-quality welds, repeatable accuracy, and efficient production cycles. The PLC-based control system provides seamless synchronization between robotic operations, safety systems, and peripheral devices, optimizing productivity while maintaining operator safety and ease of maintenance.

Key Features

- Advanced MIG welding robot cell designed for high-precision automotive component welding.

- Integration of PLC-based control system for full automation and monitoring.

- Seamless coordination between robot, welding power source, and safety interlocks.

- Supports multi-axis robotic welding with accurate path control.

- User-friendly HMI interface for process control and parameter adjustments.

- Compact layout with optimized space utilization for industrial environments.

- Designed to deliver consistent weld quality and reduced production downtime.

- Successfully commissioned and operational at Gujarat Caparo for mass production.

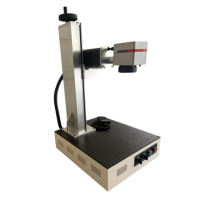

Max Make Laser Marking Machine

The Max Make Laser Marking Machine is a high-precision industrial marking solution designed for permanent engraving, coding, and traceability on a wide range of materials including metal, plastic, aluminum, stainless steel, and more. Powered by MAX Photonics fiber laser technology, it delivers high marking accuracy, fast processing speed, and superior beam quality for clear and durable results.

This machine supports applications such as QR codes, barcodes, serial numbers, logos, and component marking, making it ideal for industries like manufacturing, automotive, electronics, and metal fabrication. With low maintenance, long service life, and energy-efficient performance, the Max Make Laser Marker ensures reliable 24/7 industrial operation.

Engineering Excellence in Every Project

Delivering end-to-end industrial projects that enhance productivity, safety, and performance through smart automation and expert integration.